|

Campus EfficiencyWhat ways can a donor help the seminary? Here is one unique story

In the summer of 2014, Westminster was given a generous gift with a specific purpose in mind: make the campus more energy-efficient. After several months of work, both on Machen Hall and the Carriage House, the seminary is now poised to save a significant amount on its energy bill this winter. We spoke with Mark Wilson, Vice President of Finance, and Rich Maienshein, manager of physical plant, about what the money went towards and how it will ultimately save the seminary thousands of dollars every year in heating and energy. There were several projects that could have been done with the money allocated for this project. When the physical plant team received consultation on what to do, several important things came up. First, it was necessary to change the heating in the Carriage House from oil to natural gas. Second, the primary burner in the basement of Machen Hall needed to be replaced entirely. Finally, a new system needed to be put in place in Machen to better manage heating during the winter.

The biggest part of the project was changing the heating from oil to natural gas in the Carriage House. The Carriage house did not have a gas line, so a line needed to be dug from Machen to the Carriage House. For one week in September and October, Huntington Mechanical dug a trench from Machen to the Carriage House, laying the new gas line and diverting traffic. This part of the project was the only one visible to anyone who visited campus, and the next week the only evidence remaining was a fresh layer of asphalt where the trench was dug.

Shortly after the new gas line was finished a new boiler was put in the Carriage House, and that phase of the project was finished.

The second part of the campus efficiency project was replacing an old gas boiler in the basement of Machen. For about 20 years, Machen’s primary boiler operated without much difficulty, but it was much less efficient than newer models. A newer model ensures a more efficient use of natural gas, and helps cut down on energy costs as well. As a part of this phase, the pipes in the boiler room were also insulated properly. As Rich says, “Before the pipes were insulated, the boiler room would become a ‘boiling room!’ All the heat that the boiler put out was just exiting through the pipes in the boiler room making it extremely hot in there. Now, with the insulation, the heat is not wasted in the boiler room and is transferred to the offices and rooms above where it should be.”

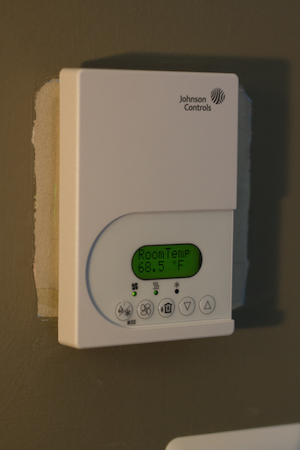

The final phase of the project was improving the heating control in Machen Hall, with the help of Dynamic Controls. Before this project, each office had its own control and “every man did what was right in his own eyes” as far as heating was concerned. The thermostats in each of the rooms were very old, and some of them didn’t display the temperature accurately. Now, the thermostats are both brand-new and accurate.

What’s more, because of the new thermostats, heating throughout the building is controlled by Rich by means of a website. Whether in his office or at home, Rich can see the exact temperature displaying on each thermostat and control how they are set. Rich says, “this allows us to turn the heating down to 62 at night and on the weekends, and especially when the seminary is closed for holidays.” This kind of control, of course, now ensures that Rich will have no enemies on campus during the winter months. An efficiency project is not a glamorous thing to support, but it ultimately saves the seminary thousands each year. Mark Wilson provides some perspective: “If we had received the money from that gift as general instead of restricted, we probably wouldn’t have allocated those funds for a project like this. This kind of a project would have taken several years to pay for itself, so we probably would have simply allocated it for operating expenses or seminary initiatives. However, because the gift was restricted, and all the money went towards the efficiency project, now those operating expenses and seminary initiatives are the direct beneficiaries of the savings we get from a more efficient campus.” While the exact amount that will be saved from the improvements is hard to predict, at the very least the seminary will save 25% on heating the Carriage House alone by converting to gas from oil. While the initial results of the project are certainly encouraging, there is still much that could be done to improve campus efficiency. Machen is an old building and there are many improvements that could be made to cut down on draftiness and improve equipment. The library is on a separate gas line, and improvements could be made to the boiler and systems there as well. Right now, Rich only has complete control over the temperatures in Machen hall; one possibility would be to synchronize all the buildings so he can monitor temperatures throughout the campus. Nevertheless, through the generosity of kind donors, the seminary’s efficiency has improved dramatically. Our hope and prayer is that the Lord would continue to provide for the seminary, that he would use it to his glory for many years to come. |